Nissan Forkslift 1F Series Specifications

In the new 1F Series, Nissan brought together the experience of more than 50 years of building superior forklifts and its vast automotive technologies and know-how. The result is superior reliability, productivity and environmental friendliness, matched with lower costs throughout the life of the truck.

To meet its three key objectives-meeting environmental, operator and owner needs—new Nissan super-low-emission engines, drivetrains and other technologies have been used. The offspring of a proud lineage, the 1F Series gives you the reliability to keep on going.

Key Objectives:

- For the Environment: Low Emission and Low Noise

- For Operators: Safety, Comfort and Ease of Operation

- For Owners: Reduced Total Lifecycle Cost

Objective 1: For the Environment

Low Emission and Low Noise

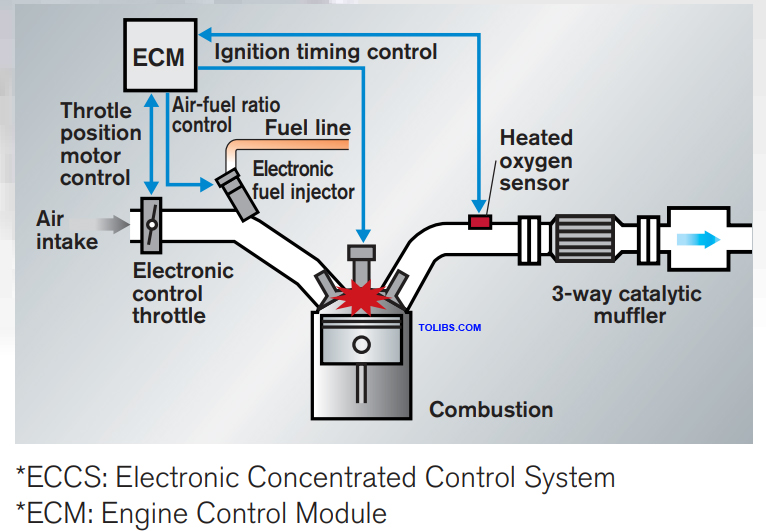

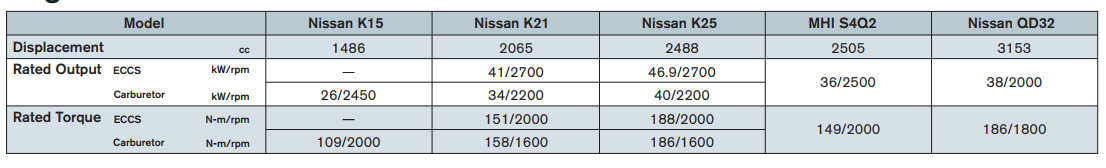

The 1F Series brings together improved environmental protection and a more comfortable working environment. Nissan’s industry-leading engine technologies have been applied to provide both high performance and super-low emission levels. The Series features the completely new Nissan QD32 diesel engine, advanced ECCS gasoline and LPG engines in a low-noise design.

Improved Working Environment

Ultra-low Noise Levels

The 1F Series is designed to provide significantly lower noise levels, which helps reduce operator fatigue and allows the operator to better hear the surrounding environment.

Soft Landing System

Even if the operator continuously holds the control lever down, the soft landing function will help ensure that the forks smoothly decelerate just before reaching the ground. The system also prevents clatter as the fork descends.

Diesel Engine

The new QD32 diesel engine meets the EU Stage IIIA, and is in compliance with US EPA Tier III regulations. It’s based on engines proven through use over millions of miles in Nissan Commercial Vehicles. In addition, the Quick Glow System provides greatly improved starting in cold weather.

Gasoline and LPG Engines

The ECCS engines represent a further evolution of world-leading clean emission performance, with greatly reduced CO, HC and NOx emissions compared to carburetor models.

ECCS and 3-way Catalytic Muffler

This design includes an automotivetype closed-loop feedback system. Once combustion occurs, a sensor measures oxygen concentration in the exhaust gases before they enter the 3-way catalyst, then sends a signal to the ECM. Based on this signal, the ECM makes the proper air/fuel ratio adjustments, resulting in extremely low emission levels.

Objective 2: For Operators

Safety, Comfort and Ease of Operation Safety and Comfort

The Nissan-exclusive Swaying Control System helps provide greater control and stability when turning the forklift. It’s part of a full range of safety equipment and features that help make for safer operations. The low-noise, low-vibration design provides a much more comfortable operating environment and reduced operator fatigue means the operator can concentrate on the job at hand.

Swaying Control System

The Nissan-exclusive Swaying Control System*, which provides confident driving control when turning the forklift, is standard equipment.

Low Center of Gravity Design

Designed for a low center of gravity, the 1F Series provides excellent stability during operation. For difficult working conditions, this can be further enhanced with the use of double tires.

Low-noise, Low-vibration Design for More Comfortable Operations

Powertrain Float Reduces Vibrations

An automobile-style floating powertrain and rigid frame and chassis reduce the transmission of vibrations to the operator, making longer, more comfortable hours of operation possible.

Speed Selector (Option)

Select maximum speed settings based on operator skill level, or the truck operation characteristics of your operations. Gasoline/LPG ECCS models only.

Safety Features

Three seat-actuated safety features have been provided as standard equipment.

Mast Lock System

The Mast Lock System, standard on all models, automatically locks all lifting and tilting functions when the operator leaves the seat.

Parking Brake Warning Buzzer

An automobile-style parking brake adds to convenience and safety, with a warning buzzer sounding when the operator leaves the seat without setting the parking brake.

Automatic Transmission Power Cut-off System

When the operator leaves the seat or is not seated properly and the shift lever is not in the neutral position, transmission is automatically shifted to neutral, cutting off power from the engine.

The 1F Series is designed to provide a simply better and more productive place to work. The new Multifunctional LCD Meter, spacious operator compartment, standard full suspension seat, smart control layout and responsive handling, all combine to provide operators with a surprisingly comfortable way to get through every workday.

Multifunctional LCD Meter

The large, easy-to-see Multifunctional LCD Meter lets the operator check on all aspects of operational status at a glance. The many functions such as the Selfdiagnosis System, PIN Access and Service Reminder System ease truck operation and maintenance.

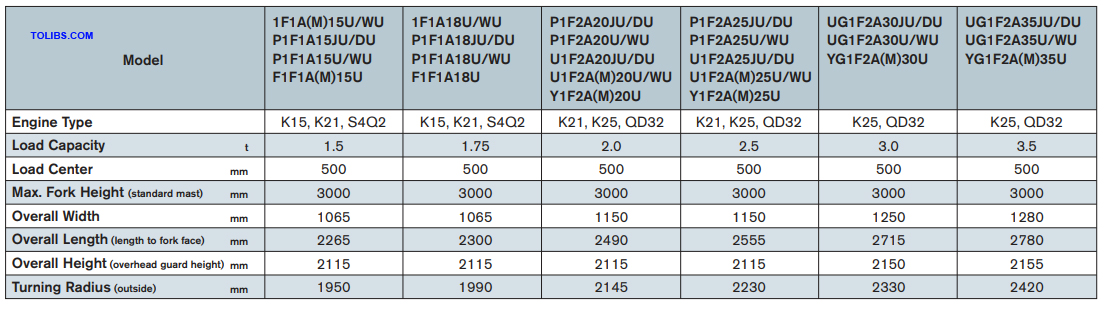

Specifications Pneumatic Tire / Engine-powered Models 1.5-3.5 ton

ENGINE:

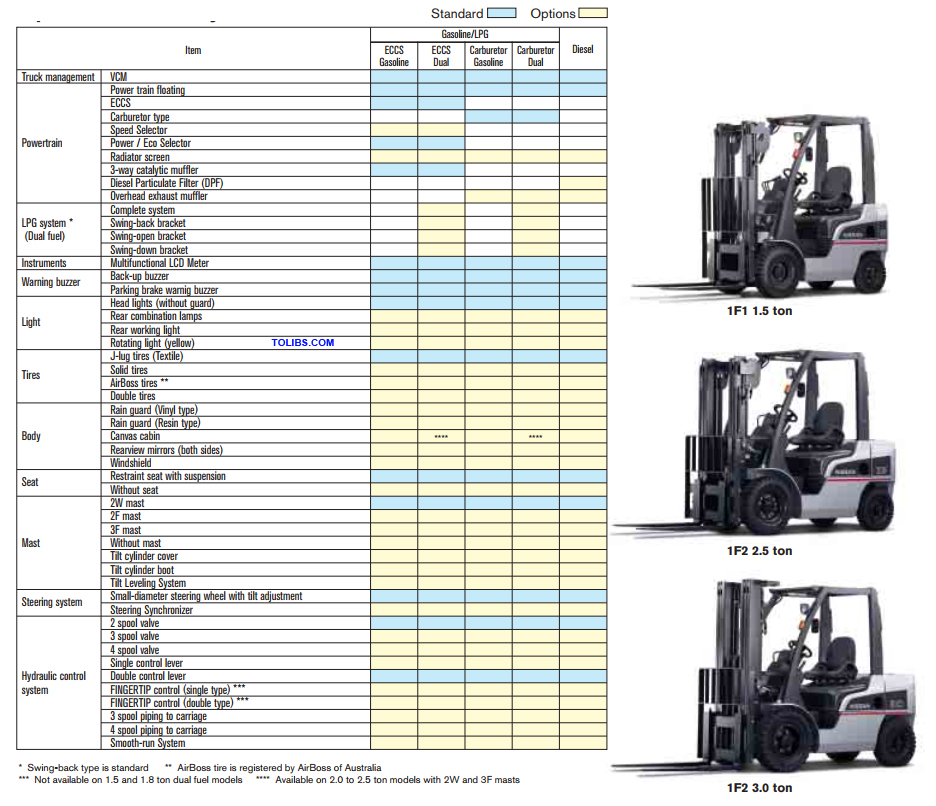

Option Availability

Speedometer

The Multifunctional LCD Meter includes an easy-to-read speedometer; travel speed is displayed whenever the forklift is moving at 4 kph or higher.

Small-diameter Steering Wheel with Tilt Adjustment

The easy-handling steering wheel with tilt adjustment helps to provide the ideal operating position.

Simple, Small-stroke F/R Lever

The forward-reverse lever swings through a smaller arc than previous models, meaning less effort and less total time spent on this basic, often-performed function.

Automobile-style Light/Turn-signal Lever

The 1F Series features the thoughtful use of an automobile-style light and turn-signal lever, with simple actions that let the operator focus on the job.

Single Control Lever (Option)

Nissan’s original Single Control Lever allows for simultaneous lifting and tilting operations, for greater productivity (double control levers are also available).

Super Wide-view Mast with Outer Chain

Outer chains and an extrawide opening between the inner masts give the operator superior forward visibility, enhancing the efficiency of operations.

Restraint Seat with Suspension

This special seat, standard on all models, helps provide a secure, comfortable control center for the operator, with ample suspension and hipsupport grips.

Wide-open Foot Space and Automobile-style Pedal Layout

A comfortable pedal angle, automobile-style pedals and a wide area free from obstructions below the seat provide more ergonomic operation.

Easy Entry and Exit

A low floor height makes it easier to step into and out of the forklift, made even more secure with a non-skid steel step.

Objective 3: For Owners

Reduced Total Lifecycle Cost High Productivity and Low Fuel Consumption

The purchase price is not the true cost of the forklift: throughout the lifetime of the truck it will require fuel, maintenance and labor costs. In the 1F Series, Nissan very carefully considered the total lifecycle cost of a forklift and answered this with effective solutions for reduced cost and superior productivity.

These begin with improved ECCS gasoline/LPG engines and the new Nissan QD32 diesel engine, which provide higher performance and reduced fuel consumption. They continue with a superior turning radius and smart, easy-operating controls and a range of available options to give operators better, more efficient control and provide higher productivity.

FINGERTIP Control Lever (Option)

The optional fingertip control system uses electro-hydraulic levers for control of travel direction, horn, tilt and lift operations with just a slight touch of the finger, providing greater ergonomics and productivity. Both single and double control levers are available.

Making Maintenance Easy and Cost Effective

Maintenance is one of the major costs throughout the lifecycle of a forklift. A forklift with the reliability to operate with the lowest amount of downtime also helps to reduce cost over time. The Self-diagnosis System and easy access for maintenance assure that the time required for maintenance and service is kept to a minimum. Renowned for its top-class reliability, Nissan has further enhanced this with new Nissan engines and drivetrains.

Easy Truck Management

VCM and CAN

The Vehicle Control Module (VCM) makes use of information provided by a number of sensors around the forklift, transmitted through the Controller Area Network (CAN), to provide a range of information and control functions. Durability of the VCM has also been increased through the use of waterproof connectors and enclosures meeting the IP65 standard for dustand water-tightness.

Options and Attachments to Meet Varied Customer Needs

These are just a selection of the many options and attachments available for the 1F Series. For more information, please contact your local Authorized Nissan Dealer.

Smooth-run System

Two different types of accumulators absorb the shocks transmitted from the road surface making both load handling and travel smoother. This offers extra benefits when working with delicate loads on rough surfaces.

LPG Swing-down Bracket

This ergonomically designed swing-down bracket greatly assists in for the lifting and lowering of tanks. A new and improved design also provides better rearward visibility (available on all LPG-powered models).

Read For Nissan Forklift 1F-Series Diesel 2-3,5 ton Service Guide Document