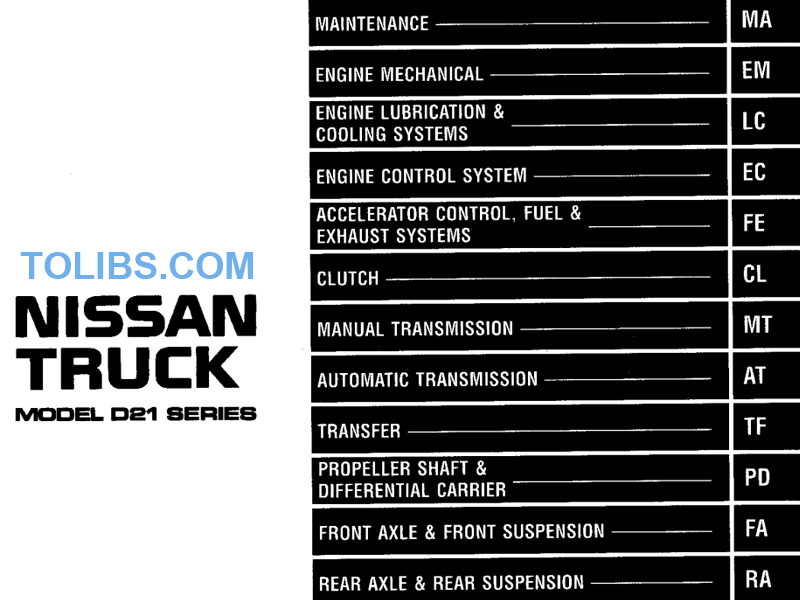

Nissan Truck D21 1997 Service Manual

This manual contains maintenance and repair procedures for the 1997 Nissan TRUCK. In order to assure your safety and the efficient functioning of the vehicle, this manual should be read thoroughly. It is especially important that the PRECAUTIONS in the GI section be completely understood before starting any repair task. All information in this manual is based on the latest product information at the time of publication. The right is reserved to make changes in specifications and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of the technician and the efficient functioning of the vehicle. The service methods in this Service Manual are described in such a manner that the service may be performed safely and accurately. Service varies with the procedures used, the skills of the technician and the tools and parts available. Accordingly, anyone using service procedures, tools or parts which are not specifically recommended by NISSAN must first be completely satisfied that neither personal safety nor the vehicle's safety will be jeopardized by the service method selected.

TEST VALUE AND TEST LIMIT (GST ONLY - NOT APPLICABLE TO CONSULT-II)

The following is the information specified in Mode 6 of SAE J1979. The test value is a parameter used to determine whether a system/circuit diagnostic test is “OK” or “NG” while being monitored by the ECM during self-diagnosis. The test limit is a reference value which is specified as the maximum or minimum value and is compared with the test value being monitored. Items for which these data (test value and test limit) are displayed are the same as SRT code items. These data (test value and test limit) are specified by Test ID (TID) and Component ID (CID) and can be displayed on the GST screen.

Supplemental Restraint System (SRS) "AIR BAG"

The Supplemental Restraint System "Air Bag", used along with a seat belt, helps to reduce the risk or sever ity of injury to the driver in a frontal collision. The Supplemental Restraint System consists of an air bag mod ule (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp, wiring harness, a crash zone sensor (4WD models) and spiral cable. Information necessary to service the system safely is included in the RS section of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN dealer. Improper maintenance, including incorrect removal and installation of the SRS, can lead to per sonal injury caused by unintentional activation of the system. Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this Service Manual. SRS wiring harnesses are covered with yellow insulation either just before the harness connectors or for the complete harness, for easy identification.

GENERAL MAINTENANCE

General maintenance includes those items which should be checked during the normal day-to-day operation of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform checks and inspections themselves or they can have their NISSAN dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified. Tires Check the pressure, including the spare, with a gauge periodically when at a service station, and adjust to the specified pressure if necessary. Check carefully for damage, cuts and excessive wear. Wheel nuts When checking the tires, make sure no nuts are missing, and check for any loose nuts. Tighten if necessary. Tire rotation Tires should be rotated every 12,000 km (7,500 miles) for 2WD models and every 6,000 km (3,750 miles) tor 4WD models. Wheel alignment and balance If the vehicle pulls to either side while driving on a straight and level road, or if you detect uneven or abnormal tire wear, there may be a need for wheel align ment. If the steering wheel or seat vibrates at normal highway speeds, wheel balancing may be needed.Windshield wiper blades Check for cracks and wear if they do not wipe properly.

Doors and engine hood Check that all doors, engine hood and tailgate operate smoothly. Also make sure that all latches lock securely. Lubricate if necessary. Make sure that the secondary latch keeps the hood from opening when the primary latch is released. When driving in areas using road salt or other corrosive materials, check lubrication frequently. Lamps Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and other lamps are all operating properly and installed securely. Also check headlamp aim.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per forming periodic maintenance, cleaning the vehicle, etc. Warning lamps and buzzers/chimes Make sure that all warning lamps and buzzers/chimes are operating properly. Windshield wiper and washer Check that the wipers and washer operate properly and that the wipers do not streak. Windshield defroster Check that the air comes out of the defroster outlets properly and in suffi cient quantity when operating the heater or air conditioner. Steering wheel Check that it has the specified play. Be sure to check for changes in the steer ing condition, such as excessive play, hard steering or strange noises. Free play: Less than 35 mm (1.38 in) Seats Check seat position controls such as seat adjusters, seatback recliner, etc. to make sure they operate smoothly and that all latches lock securely in every position. Check that the head restraints move up and down smoothly and that the locks (if equipped) hold securely in all latched positions. Check jump seats for smooth operation. Seat belts Check that all parts of the seat belt system (e.g., buckles, anchors, adjusters and retractors) operate properly and smoothly and are installed securely. Check the belt webbing for cuts, fraying, wear and damage. Clutch pedal Make sure the pedal operates smoothly and check that it has the proper free play. Brakes Check that the brakes do not pull the vehicle to one side when applied. Brake pedal and booster Check the pedal for smooth operation and make sure that it has the proper distance under it when depressed fully. Check the brake booster function. Be sure to keep floor mats away from the pedal. Parking brake Check that the lever has the proper travel and make sure that the vehicle is held securely on a fairly steep hill when only the parking brake is applied. MA-3 Reference page MA-19 MA-19, FA-8 MA-22 ST-7 MA-23 CL-5 BR-11, 16 BH-27.

Automatic transmission "Park" mechanism Check that the lock release button on the selec tor lever operates properly and smoothly. On a fairly steep hill check that the vehicle is held securely with the selector lever in the "P" position without applying any brakes.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g., each time you check the engine oil or refuel). Windshield washer fluid Check that there is adequate fluid in the tank. Engine coolant level Check the coolant level when the engine is cold. Radiator and hoses Check the front of the radiator and clean off any dirt, insects, leaves, etc., that may have accumulated. Make sure that the hoses have no cracks, deformation, deteriora tion or loose connections. Brake and clutch fluid levels Make sure that the brake and clutch fluid levels are between the "MAX" and "MIN" lines on the reservoirs. Battery Check the fluid level in each cell. It should be between the "MAX" and "MIN" lines. Engine drive belts Make sure that no belt is frayed, worn, cracked or oily. Engine oil level Check the level on the dipstick after parking the vehicle on a level spot and turning off the engine. Power steering fluid level and lines Check the level on the dipstick with the engine off. Check the lines for improper attachment, leaks, cracks, etc.

Automatic transmission fluid level Check the level on the dipstick after putting the selector lever in "p" with the engine idling. Exhaust system Make sure that there are no loose supports, cracks or holes. If the sound of the exhaust seems unusual or there is a smell of exhaust fumes, immediately locate the trouble and correct it. Underbody The underbody is frequently exposed to corrosive substances such as those used on icy roads or to control dust. It is very important to remove these substances, otherwise rust will form on the floor pan, frame, fuel lines and around the exhaust system. At the end of winter, the underbody should be thoroughly flushed with plain water, being careful to clean those areas where mud and dirt can easily accumulate. Fluid leaks Check under the vehicle for fuel, oil, water and other fluid leaks after the vehicle has been parked for a while. Water dripping from the air conditioner after use is normal. If any leaks or gasoline fumes are evident, check for the cause and correct it immediately.

Two different maintenance schedules are provided, and should be used, depending upon the conditions under @l which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic maintenance at the same mileage/time intervals.

SCHEDULE 1

Follow Periodic Maintenance Schedule 1 if your driving habits frequently include one or more of the following gt driving conditions:

- Repeated short trips of less than 5 miles (8 km).

- Repeated short trips of less than 10 miles (16 km) with outside temperatures remaining below freezing.

- Operating in hot weather in stop-and-go "rush hour" traffic.

- Extensive idling and/or low speed driving for long distances, such as police, taxi or door-to-door delivery use.

- Driving in dusty conditions.

- Driving on rough, muddy, or salt spread roads.

- Towing a trailer, using a camper or a car-top carrier.

SCHEDULE 2

Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown in Schedule 1 apply to your driving habits.

Maintenance for off-road driving (4x4 only)

- Whenever you drive off-road through sand, mud or water, more frequent maintenance may be required of the following items:

- Brake pads and discs

- Brake lining and drums

- Brake lines and hoses

- Wheel bearing grease and free-running hub grease

- Differential gear oil, transmission and transfer fluid

- Steering linkage

- Propeller shaft and drive shafts

- Air cleaner filter

- Clutch housing (Check water entry. Refer to MA-16.)