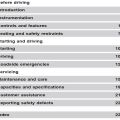

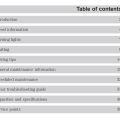

Ford Tractor 2000 / 3000 / 4000 / 5000 Operator’s Manual

This Operators Handbook has been specially prepared to familiarize you with the function, operation and regular servicing of the Ford Tange of tractors. Included in this range are the Ford 2000 and 3000 Agricultural Highway, Narrow and Vineyard tractors and the Ford 4000 and 5000 Agricultural tractors.

The details of operation and maintenance which are peculiar to Select-O-Speed tractors and Petrol engined tractors are covered in Sections K and L. These sections should be read in conjunction with the main book.

A. DRIVING THE TRACTOR

The basic function of starting and driving the tractor, and the controls involved are covered in this section. You should pay particular attention to the pre-starting check. the running-in items and the safety precautions. Controls relating to the operation of the tractor hydraulics and power take-off are detailed under separate sections.

B. THE HYDRAULIC SYSTEM

This section describes the use of Draft and Position Control and also covers the operation of the other major components and operating controls in the Hydraulic system.

C. POWER TAKE-OFF OPERATION

This section details the various types of Power Take-Off (PTO) available with Ford tractors.

D. ATTACHMENT OF IMPLEMENTS

This soction covers the use and adjustment of the three-point linkage and standard swinging drawbar. Also detailed is the towbar which is standard on the Highway tractors.

E. WHEELS AND TYRES

This section lists the standard tyres available and the recom mended working pressures. Also detailed is front and rear track adjustment and the liquid ballasting of tyres.

F. SERVICING SCHEDULE

The importance of regular servicing cannot be stressed too highly. Refer to this section when the tractor hourmeter indicates that a servicing period is imminent.

G. GENERAL MAINTENANCE AND ADJUSTMENTS

Covered in this section are items from the "Servicing Schedule" which require a moro detailed explanation of maintenance procedure, and also details of certain components which may require occasional adjustment and replacement.

H. OPTIONS AND ACCESSORIES

Various factory fitted options are available with the Ford range of tractors. This section gives details and method of operation of the major options. Information is also given of certain typos of accessories.

I. SPECIFICATIONS

J. INDEX

K. SELECT-O-SPEED

(Optional Section) Contained within this section are those items which relate specifically to tractors fitted with Select-O-Speed transmissions. Refer to Sections A to I of the Operator's Handbook for all other information and data.

L. PETROL ENGINED TRACTOR

(Optional Section) Contained within this section are those items which relate specifically to tractors fitted with Petrol engines. Refer to Sections A to K of the Operator's Handbook for all other information and data.

INSTRUMENTS AND WARNING LIGHTS (Figure A1)

PROOF METER The proofmeter (1) registers the engine revolutions per minute (r.p.m.) and the number of 'hours' the tractor has worked. The indicated engine r.p.m. must be multiplied by 100 to determine the true engine speed. Tractor ground speeds, power take-off and belt pulley speeds for certain indicated engine r.p.m. are listed on a decal beneath the proofmeter. Further information on these speeds may be found in Section I of this Handbook. The 'hours' (2) measured are based on an average engine speed and do not, therefore, necessarily correspond to clock hours. The service periods are specified in 'hours· and the hourmetcr should be watched for when they occur.

SPEEDOMETER

On Highway tractors the proofmeter is replaced with a speedometer to comply with Road Traffic Regulations.

WARNING LIGHTS

The generator warning light (3) is illuminated when the key starter switch, (6) Figure A4, is turned on. the engino started and run-up to idle spood. If the light remains on at highor revolutions this indicates that the battery is not being charged. If the light remains on stop the engine and establish the reason Tho engine oil pressure warning light (4) is illuminated when tho key starter switch is turned on. The light should go out immediately the engine starts but if it remains on stop the engine and investigate the cause.

TEMPERATURE GAUGE

The temperature gauge () measures the temperature of the engine coolant and at normal engine operating temperatures the needle should be halfway between the blue (cold) and the red (hot) zones The gauge is not operative when the key starter switch is in the 'off' position.

"RUNNING-IN"

The 'running-in' period of a tractor's life is oxtromoly important and the following instructions should be followed very closely during the first 50 hours of operation:

- Avoid overloading the engine.

- Use the lower gear ratios when pulling heavy loads and avoid continuous operation at constant engine speeds.

- Check the instruments frequently and keep the radiator and oil reservoirs filled to their recommended levels.

- Avoid prolonged 'no load' operation at either high or low engine speeds.

Whilst the above instructions are particularly important during the 'running-in' period, following them throughout the tractor's life will prove beneficial to the overall performance and efficiency of your tractor.

STARTING THE ENGINE TRACTOR SEAT (Figure A3)

Prior to starting the engine adjust the tractor seat to the most comfortable driving position. Both the steel pan and the contoured type of seat are adjustable fore and aft; the steel pan seat utilising the pairs of holes in the seat mounting bracket and the contoured seat by adjustment along the angled slots (1) in the seat base.

The tension in the contoured seat may be adjusted for the operator's weight by turning the cranked handle (2) until tho two indicators (3) align. This adjust ment should be made with the operator in the seat. All types of seat may be tilted back to permit the operator to stand.

STARTING (Figure A4)

- Check that the engine stop control (1) is pushed in and the handbrake (2) engaged.

- Depress the foot operated clutch pedal (3) positioned on the left-hand side of the gearbox, and set the main and high/low gear lever (4) in "Neutral' (the starter motor can only be actuated when the high/low lever is in this position).

- Set the hand throttle lever (5) half open (pulling the lever downwards opens the throttle.)

- Insert the starter key (6) and turn clockwise to the first position (8) to operate the instrument and warning lights and further clockwise (9) to engage the starter.

- When the engine starts release the key and allow it to return to the first position.

- Immediately check to ensure that the generator and oil pressure warning lights go out.

Highway tractors and for certain territories Agricultural tractors, are fitted with a foot throttle (10) as well as a hand throttle. The throttle pedal is situated on the right-hand footplate. The operation of the foot throttle over-rides the hand throttle which should be set to idling speed when the foot throttle Is being used.

COLD WEATHER STARTING

When starting under cold weather conditions it is important that the starter key be held in the 'start' position continuously until the ongine starts. This allows heat to build-up in the combustion chambers. At very low tempera tures it may be necessary to hold the key in position for up to 35-40 seconds. Do NOT operate the key in a series of short jabs. If the engine does not start after 40 seconds, allow 4-5 minutes for the battery to recover then repeat the starting procedure. As a further aid to cold starting, the Ford 3000 and Ford 5000 are fitted with an excess fuel button. Figure A5, on the side of the fuel injection pump. This button should be depressed prior to starting the tractor and will be automatically disengaged when the engine fires. If the engine does not continue to run the button must be depressed again before another attempt is made to start the engine. Optional starting aids are available for extreme cold conditions and details of these are given in Section 'H'.

DRIVING THE TRACTOR

For fuel economy and minimum engine wear it is important to select the correct gear for a particular operation. To drive the tractor select the desired gear using the gear change and high/ low gear shift levers, Figure A6, in conjunction with the decal below the instrument cluster. Engage the clutch whilst increasing the engine speed slightly. The clutch pedal should not be used as a footrest as prolongod 'riding· of tho clutch may cause damage.

To stop the tractor depress the clutch and apply both brake pedals, (11) Figure A4 and place the main and the high/low gear shift levers in the 'Neutral' position. Apply the handbrake situated on the left-hand side, (2) Figure A4, of the tractor seat on the Ford 2000 and 3000, and on the right-hand side of the scat on tho Ford 4000 and 5000. Pull out the engine stop control and turn the starter key anti-clockwise, (6) Figure A4, to the 'off" position.