Nissan Forklift Operator’s Procedures manual

A Word to NISSAN FORKLIFT Operators

This booklet describes operating procedures, daily cares and simple maintenance for safe usage of your NISSAN FORKLIFT. We urge you to read this booklet carefully before operating the lift truck to familiarize yourself with safety instructions. These instructions will not only reduce mechanical troubles of your lift truck, but may also save your life.

If you encounter any problems with your NISSAN FORKLIFT truck, contact the authorized NISSAN FORKLIFT dealer in your area and request a complete check-up. The dealership will insure that your Lift Truck is serviced in accordance with the latest factory approved methods.

This Operator’s Manual has been prepared on the assumption that your truck is fully equipped (including all optional equipment). Thus if you have any questions regarding equipment, please contact your authorized NISSAN FORKLIFT dealer.

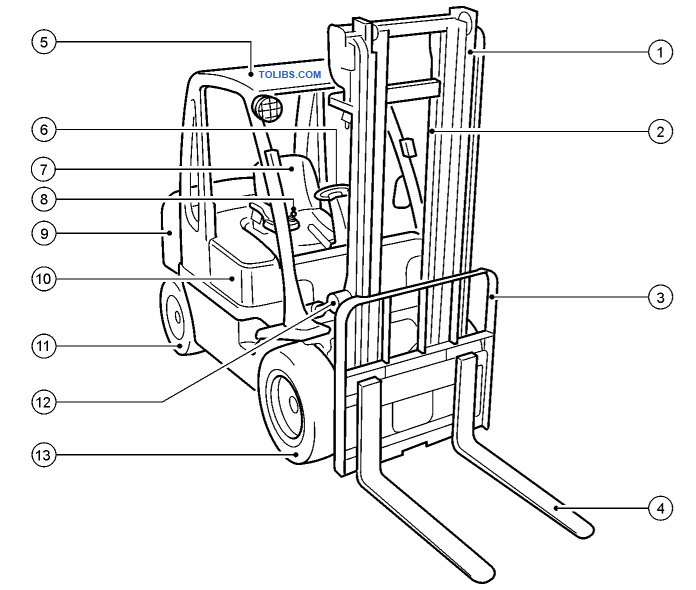

NAME OF COMPONENTS

- Mast

- Lift cylinder

- Backrest

- Fork

- Overhead guard

- Steering wheel

- Operator’s seat

- Joystick lever

- Counterweight

- Top panel

- Rear tire

- Tilt cylinder

- Front tire

APPROACH ANGLE, DEPARTURE ANGLE AND GANGWAY

Tilt the mast back to the maximum without load. Check the approach angle, departure angle, and ramp breakover angle to make sure the underside of the forklift will not contact the load carrying platform or the ground.

When using a gangway, make sure the planks are capable of supporting the truck weight. Drive forklift on and off the carrier slowly. When winching the forklift onto a load carrying platform, be sure to attach the cable to the traction pin. Do not ride on the forklift while it is being winched. Be sure to use lashing points and firmly secure the truck to the load carrying platform. When hoisting the forklift, be sure to use the lifting points. Turn off the key switch and remove it.

METERS, GAUGES, INDICATOR AND WARNING LAMPS

Fuel meter

With the ignition switch ON, the fuel meter indicates the approximate amount of fuel in the tank. Always top up the fuel tank.

Water temperature meter

When the ignition switch is set at ON, the water temperature meter operates and pointer indicates coolant temperature. During ordinary operation, the pointer will remain about the center range of the gauge. If the pointer indicates “H” position and remains there for more than a few minutes, stop the Lift Truck and cool the engine at idling speed. After stopping the engine, check the coolant level and fan belt deflection.

Hour meter

The hour meter operates when the ignition switch is in the ON position. The dial of the hour meter advances one number when the ignition switch remains in the ON position for an hour. Consequently, the number of the hour meter indicates total operating period of hour.

Cooling water level warning lamp (Option)

This lamp comes on when the ignition switch is turned to START. If the lamp comes on while the forklift is in operation, it indicates that the coolant in the radiator reservoir tank has dropped below the MIN. level.

Air cleaner plugging indicator lamp (Option)

This lamp comes on when the air cleaner is clogged. If the lamp comes on while driving, clean the air cleaner immediately.

Torque converter oil temperature warning lamp

Under normal operating conditions, the warning lamp turns on when the key switch is turned to the START position and turns off when the engine starts. The lamp will turn on during engine operation whenever the torque converter oil temperature exceeds the normal level.

Emergency seat belt warning lamp

The seat belt warning lamp comes on when the seat belt is not fastened with the key switch turned ON.

Parking brake warning lamp

The parking brake warning lamp comes on when the parking brake is applied with the key switch turned ON.

Oil pressure warning lamp

This lamp glows red when the ignition switch turns ON and oil pressure is not built effectively in the engine lubricating system. If the lamp glows under ordinary operating conditions, stop the engine immediately and check the engine lubrication system.

Charge warning lamp

With the ignition switch ON, the warning lamp glows red when the alternator is not supplying current to the electrical system. After the engine starts, the lamp should go out, indicating that the alternator is operating properly. If the lamp glows or flickers occasionally during normal operating, the alternator and electrical system should be checked.

Fuel filter (water accumulation) warning lamp (Diesel engine)

Under normal operating conditions, the warning lamp turns on when the key switch is moved to the START position and turns off when the engine starts. The lamp will turn on during engine operation whenever the accumulated water in the fuel filter exceeds the specified level.

Backup operation switch (Optional)

The rear operating lights are used for nighttime operation and operation in poorly lit areas. The rear operating light switch controls these lights.

The light switch is a button type. When this switch is pushed, the back operation lamp comes on. When it is pushed again, the lamp goes out.

- The backup operation switch works independently of the key switch ON and OFF positions.

- Be sure to turn off the rear operating lights by pushing the knob in whenever the engine is stopped or operation suspend d. Failure to do so can result in a dead battery.

Engine idling control knob (For diesel engines: cold climate specifications are optional)

The control is located on the meter panel. Turning the knob clockwise will increase the engine idling speed. Turning the knob counterclockwise will slow down the engine idling speed. It is used to warm up the engine at starting.

Read for Nissan Forklift Operators Daily Checklist Manual Document