Ford Trader Servive Repair Manual Guide

Ford Trader Workshop Repair Manual PDF

BASIC ASSUMPTIONS

This repair manual assumes that you have certain special tools that are necessary for the safe and efficient performance of service operations on Ford vehicles and that you know how to use them properly. It also assumes that you are familiar with automobile systems and basic service and repair procedures. You should not attempt to use this manual unless these assumptions are correct and you understand the consequences described below.

SAFETY RISK

This manual contains certain notes, warnings, and other precautionary information that you should carefully read and follow to reduce the risk of personal injury to yourself or others and the risk of improper service that may damage the vehicle or render it unsafe. If there is no such information in regard to any specific service method, this does not mean there is no possibility that personal safety or vehicle safety will be jeopardized by the use of incorrect methods or tools.

POSSIBLE LOSS OF WARRANTY

The manufacturer's warranty on Ford vehicles and engines can be voided if improper service or repairs are performed by persons other than those at an Authorized Ford Dealer.

WARNING ON LUBRICANTS AND GREASES

Avoid all prolonged and repeated contact with mineral oils, especially used oils. Used oils contaminated during service (e.g.• engine sump oils) are more irritating and more likely to cause serious effects. including skin cancer. in the event of gross and prolonged skin contact.

Wash skin thoroughly after work involving oil.

Protective hand cleaners may be of value provided they can be removed from the skin with water. Do not use gasoline. paraffin, or other solvents to remove oil from the skin.

Repeated or prolonged skin contact should be avoided by wearing protective clothing if nE?cessary. Particular care should be taken with used oils and greases containing lead. Do not allow work clothing to be contaminated with oil. Dry clean or launder such clothing at regular intervals.

INSTALLATION OF MOBILE TWO-WAY RADIO SYSTEM

If a mobile two-way radio system is installed improperly or if a high-powered type is used, the control unit may be affected.

When the vehicle is to be equipped with a mobile two-way radio, observe the following precautions:

- Install the antenna at the farthest point from control units.

- Install the antenna feeder as far as possible from the control unit harnesses (at least 30 cm [11.8 in)).

- Ensure that the antenna and feeder are properly adjusted. .

- Do not install a high-powered mobile two-way radio system.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emissions control and related systems, as well as for efficient engine operation. It is strongly recommended that all serving related to these systems be done by your Authorized Mazda Dealer.

SCHEDULED MAINTENANCE SERVICES

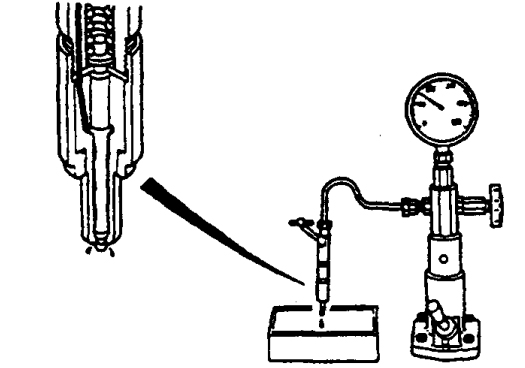

Leakage of Injector

Apply pressure SL engine: 14,715 kPa (150 kg/cm2 , 2,133 psi), HA and TF engines: 1,962 kPa (20 kg/cm2 , 284 psi) lower than the specified injection pressure and see if the fuel leaks from the nozzle injection hole. If the fuel leaks, it is necessary to disassemble, wash and recheck the nozzle or replace it.

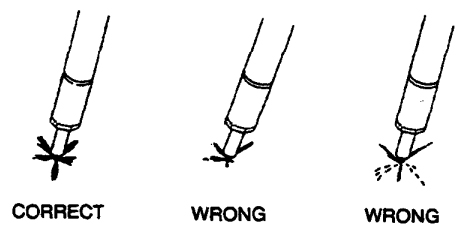

Atomizing Condition

- Connect the nozzle on the nozzle tester.

- Air bleed by operating the nozzle tester handle several times.

- Keeping the pressure gauge of the nozzle tester in the nonfunctioning condition, quickly lower the handle (lower the handle as quickly as possible so that a pulsating whistling sound can be heard). Repeat this operation several times and check the atomizing condition.

- Make sure that the fuel is atomized uniformly and properly.

- Make sure that the injection angle and direction are normal.

- If the atomizing condition is incorrect, it is necessary to disassemble, wash and recheck the nozzle, or to replace it.

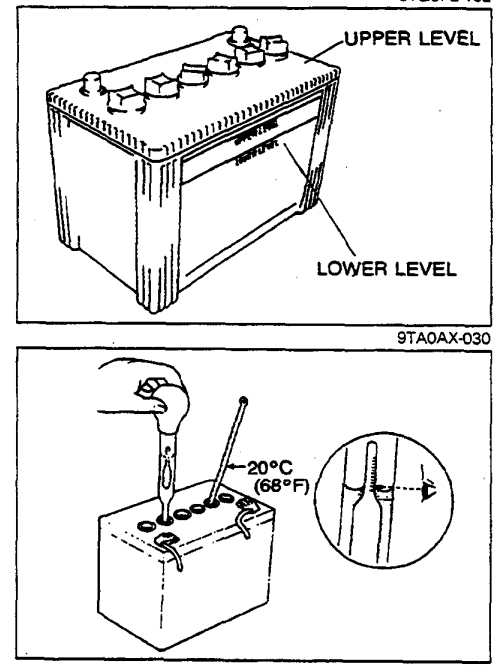

INSPECTION OF BATTERY

- Check for corrosion on the terminals and for loose cable connections.

- Check the electrolyte level. If the level is low, add distilled water to the "UPPER LEVEL" mark.

- Check the specific gravity with a hydrometer. If the specific gravity reading is 1.23 or less, recharge the battery. (Refer to Section G.)

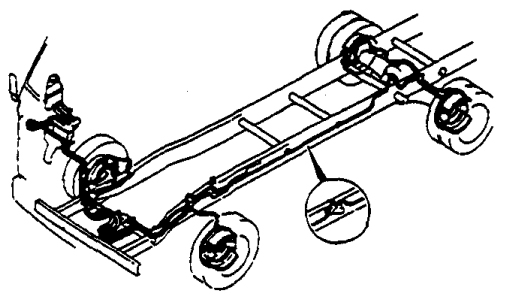

INSPECTION OF BRAKE AND CLUTCH LINES, HOSES AND CONNECTIONS

Check the brake and clutch lines and hoses for proper attach. ment and connections. There should not be any leaks, cracks, chafing, abrasion, deterioration, etc. on the lines or connections.